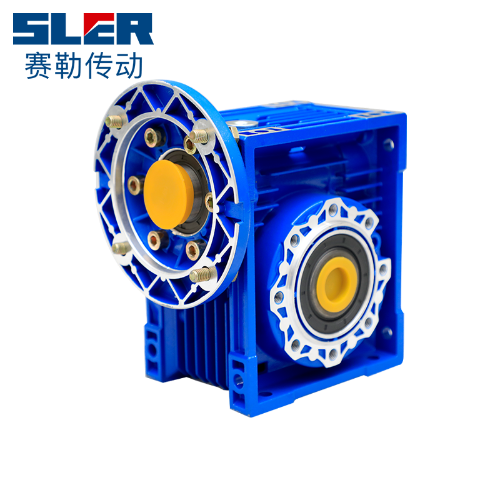

A worm gear speed reducer unit, also known as a worm gear reducer or worm gear gearbox, is a mechanical device used to reduce the rotational speed and increase the torque output of a motor or engine. It consists of two main components: a worm gear and a worm wheel.

The worm gear is a cylindrical gear with helical threads, often referred to as a worm. It resembles a screw, with the threads wrapped around the cylindrical body. The worm wheel, on the other hand, is a gear that meshes with the worm and has teeth that are perpendicular to the axis of rotation. The worm wheel is larger in diameter than the worm gear.

When the worm gear is rotated by the input motor or engine, the helical threads on the worm engage with the teeth of the worm wheel. As the worm rotates, it causes the worm wheel to rotate as well, but at a reduced speed. The reduction ratio of a worm gear speed reducer is determined by the number of teeth on the worm wheel compared to the number of threads on the worm gear.

One important characteristic of a worm gear speed reducer is its ability to provide a high reduction ratio in a single stage, making it suitable for applications requiring a significant decrease in speed. Additionally, the interaction between the worm gear and the worm wheel creates a self-locking effect. This means that the load cannot easily drive the worm in the opposite direction, providing inherent braking and holding capabilities.

Worm gear speed reducers are commonly used in various industrial applications where high torque and low-speed operation are required, such as conveyor systems, winches, lifting equipment, rotary tables, and many other power transmission systems. They offer advantages such as compact size, high efficiency, and smooth operation. However, it's important to note that worm gear speed reducers are not as efficient as some other types of gear systems and can generate higher heat during operation, which may require additional cooling measures.

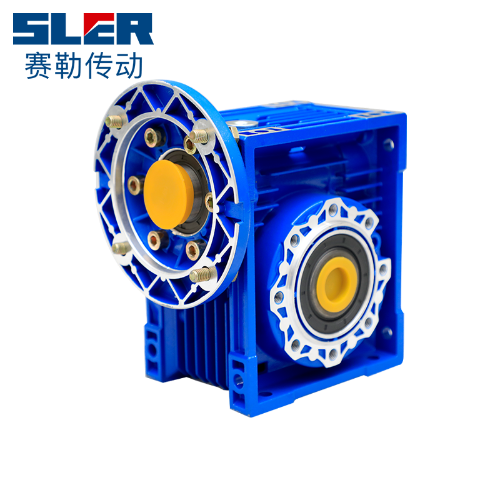

Besides,The working principle of a worm gear speed reducer unit is based on the interaction between a worm gear and a worm wheel. The unit reduces the rotational speed of the input shaft while increasing the torque output. Here's a step-by-step explanation of its working principle:

Input Shaft: The worm gear speed reducer unit receives rotational motion from an input shaft, which is typically connected to a motor or engine.

Worm Gear: The input shaft is connected to a cylindrical gear with helical threads, known as the worm gear or simply the worm. The worm gear resembles a screw, with the threads wrapped around its cylindrical body.

Worm Wheel: The worm gear meshes with a gear called the worm wheel. The worm wheel has teeth that are perpendicular to the axis of rotation and are designed to engage with the helical threads of the worm gear.

Motion Transmission: As the input shaft rotates, the threads of the worm gear cause the worm wheel to rotate as well. The direction of rotation of the worm wheel depends on the helical angle of the worm gear.

Speed Reduction: The number of teeth on the worm wheel is typically greater than the number of threads on the worm gear. This difference in tooth count creates a speed reduction effect. The worm wheel rotates at a slower speed than the worm gear, effectively reducing the rotational speed of the output shaft.

Torque Increase: The interaction between the worm gear and the worm wheel results in a significant increase in torque. The torque output at the worm wheel is greater than the torque input at the worm gear due to the mechanical advantage provided by the helical threads.

Self-Locking: One important characteristic of a worm gear speed reducer unit is its self-locking ability. The helical threads of the worm gear create a self-locking effect, preventing the load from driving the worm in the opposite direction. This inherent braking action enables the unit to hold the load in place without the need for additional braking mechanisms.

By combining the rotational motion of the input shaft, the helical threads of the worm gear, and the engagement with the worm wheel, the worm gear speed reducer unit effectively reduces speed and increases torque output. It provides a compact and efficient solution for applications requiring high torque and low-speed operation.

英语

英语 中文简体

中文简体 俄语

俄语1.png?imageView2/2/format/jp2)

1.png?imageView2/2/format/jp2)

1.png?imageView2/2/format/jp2)

a.png?imageView2/2/format/jp2)